Hy-Bor®

Portfolio of commingled boron fiber-carbon fiber unidirectional thermoset prepregs

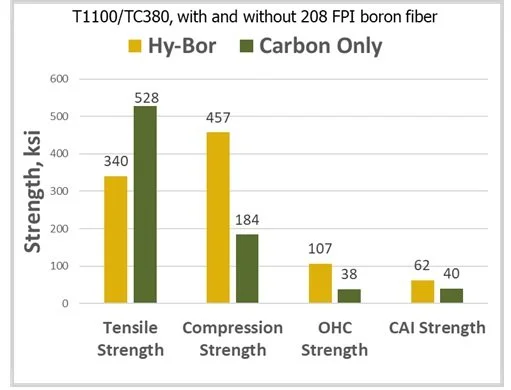

↑ 2-3X Compression Properties

↑ 2X Flexure Properties

↑ 2-3X Compression After Impact (CAI) Strength

↑ 2X Bearing Strength

Prevent microbucking and kinkband formation

Improve first bending mode damping

Reduce mass and ply count

Increase damage tolerance

Hy-Bor® is a product portfolio combining boron fiber and carbon fiber into a unidirectional thermoset prepreg which can be customized for tuned performance attributes by varying carbon fiber type, resin type, fiber volume, and other variables.

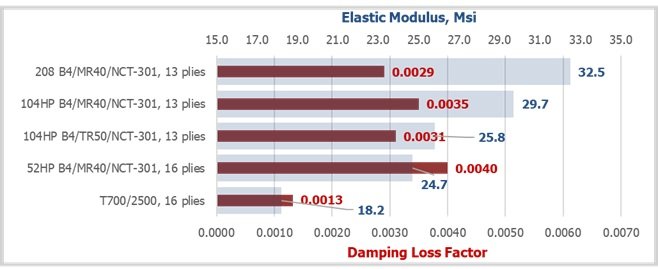

The prepreg is often used for selective reinforcement of structural composite applications which benefit from a 2-3x improvement in compression strength, open-hole compression (OHC), and compression after impact (CAI) compared to carbon fiber, and includes significant gains in bearing and flexure properties. As boron fiber is a high modulus reinforcing fiber, Hy-Bor® also has higher modulus compared to comparable standard (SM) or intermediate modulus (IM) carbon fiber prepregs.

Selective reinforcement for aerospace enables design engineers to improve stiffness, OHC and bearing strength properties significantly, allowing trade consideration for weight savings opportunities in compression-limited aerostructure parts.

For sporting goods, Hy-Bor® is generally used selectively for improvements to composite compression strength, higher stiffness, improved damage tolerance, or better damping performance.

In space applications, the positive coefficient of thermal expansion (CTE) of boron fiber combined with a pitch carbon fiber offers a lightweight structural composite capable of zero CTE in one or two dimensions.

The example above, which compares T1100/TC380 with and without boron fiber, demonstrates the 2-3x improvement in compression-related properties achievable with Hy-Bor®.

Composite Tunability

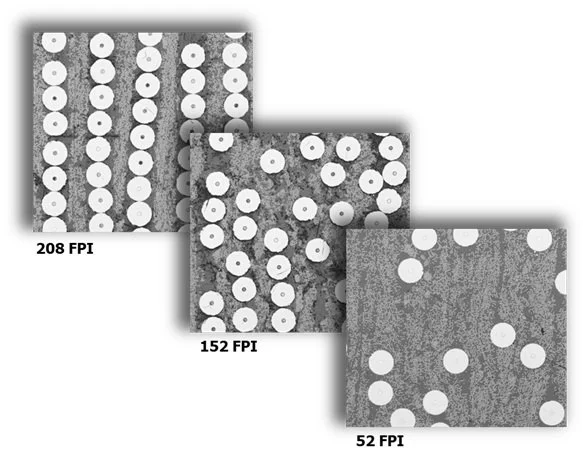

We control the fibers per inch (FPI) of the boron fiber being added to the material during our manufacturing process, which affects fiber volume and multiple composite properties.

Cross-section photomicrograph of three 0°

Hy-Bor® plies showing the 4-mil (102 micron) boron fiber surrounded by carbon fiber.

By adding boron fiber to the carbon fiber prepreg, a 2-3x improvement in damping performance is achievable depending on the boron fiber:carbon fiber ratio.

As we typically produce Hy-Bor® to order, the properties can often be tuned for the end use application based on customer need.

Notably, adding only one ply of Hy-Bor® for selective reinforcement has demonstrated performance improvement for many applications.

Our process allows for distinct tuning from the following variables.

Boron fiber FPI (52 to 208)

Boron fiber size (4-mil, 5.6-mil)

Carbon fiber type

Resin type

Density

Fiber volume

Areal weight

Cured ply thickness

Prepreg width